ANNUAL

SUSTAINABILITY REPORT

AROMATICA Sustainability Report 2021

AROMATICA Sustainability Report 2021

We make sustainable and effective products that protect life and the environment. We are actively

engaging in preserving and restoring the environment to return Earth’s environment completely intact.

Corporate profits are used for relief and sharing, and it is a channel for the gospel that has good influence on the world.

Aromatica felt guilty while producing cosmetic products as part of an ‘industry that produces large amounts of plastic wastes’ and became highly interested in the environment. Afterwards, we realized the need for corporate responsibility and action for the environment and starting with the ‘Aromatica Environmental Management and Respect for Life Declaration,’ Aromatica established policies for a sustainable environment throughout the entire process such as plant equipment, raw materials, packaging, production and sales. For this, we developed a package with a structure that can enhance recycling rates and renewed all of the products using plastic containers. Furthermore, we implemented the nation's first refill station to promote reuse of containers by spreading the refilling culture and held resource circulation campaigns, and continuously engaged in a variety of other attempts and changes.

Aromatica rethinks about packages to reduce carbon emissions starting from the product planning stage. By operating a refill station, we are establishing a culture of reusing packages, and we collect used packages ourselves to recycle and thus reduce wastes. Through this, we are pushing forward with the prototypical resource circulation system of ‘Bottle-to-Bottle.’

We strive to minimize use of the initial container (product container, labels) and secondary packaging materials (product box, other packaging materials) starting from the first planning stage of the product.

We pursue the use of alternative materials to increase recycling rates.

We are establishing a culture of ‘package reuse’ so that items are not disposed of after single use to research sustainable packages and present it to consumers as the producer.

We will present a direction for becoming the model of a national resource circulation system through the transparent PET recycling system and contribute to the establishment of a prototypical circulation culture.

In 2021, Aromatica developed containers with outstanding recycling ratings and made a full renewal to make recycling of all product containers easy. Applied subsidiary materials made only with recycled PET and PP materials for the first time in Korea, and these materials are 100% recyclable single materials to allow recycling once again after use. Instead of using pumps that cannot be recycled because they are made with various materials, PP single material one-touch caps that make resource recycling easy was applied. Compared to generally produced PET, 100% recycled PET materials that cut carbon emissions by about 50% were applied, and recyclability was further enhanced by using transparent PET instead of colored containers. (In the case of colored PET, there are difficulties in the collection stage as colored PETs must be gathered together for recycling.) Applied water soluble labels with PP materials that are easy to remove labels during separate collection and for which gravity separation is easier in the recycling process. In addition, the label adhesion area was reduced to minimize use of adhesives, thus raising recyclability.

Among products known as aluminum tubes, most of the tubes merely imitate aluminum or have appearances as aluminum. However, Aromatica developed 100% aluminum tubes that are not mixed with other materials to allow recycling.

Among products known as aluminum tubes, most of the tubes merely imitate aluminum or have appearances as aluminum. However, Aromatica developed 100% aluminum tubes that are not mixed with other materials to allow recycling.

* 100% aluminum tubes are recyclable materials, but there are no recycling rating standards for it, and it is currently being reviewed by the Ministry of Environment. Upon checking with the Ministry of Environment, it can be separately disposed of as cans.

The existing PE tubes could not be recycled as they were made with five layers of different materials labeled as other plastics. (LDPE, EVOH, ADMER, etc.) We developed a tube made with 3-layer single LDPE material to allow recycling, and it was labeled as LDPE plastics.

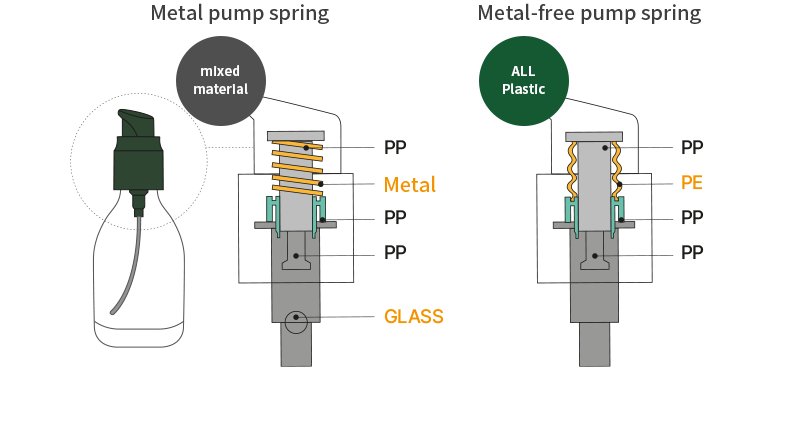

Generally used pumps are mixed materials (stainless steel, glass, PP, PE), and therefore could not be recycled. We thus removed metals and plastics and made it completely with plastics (PE, PP) to develop a metal-free pump that is easy to recycle.

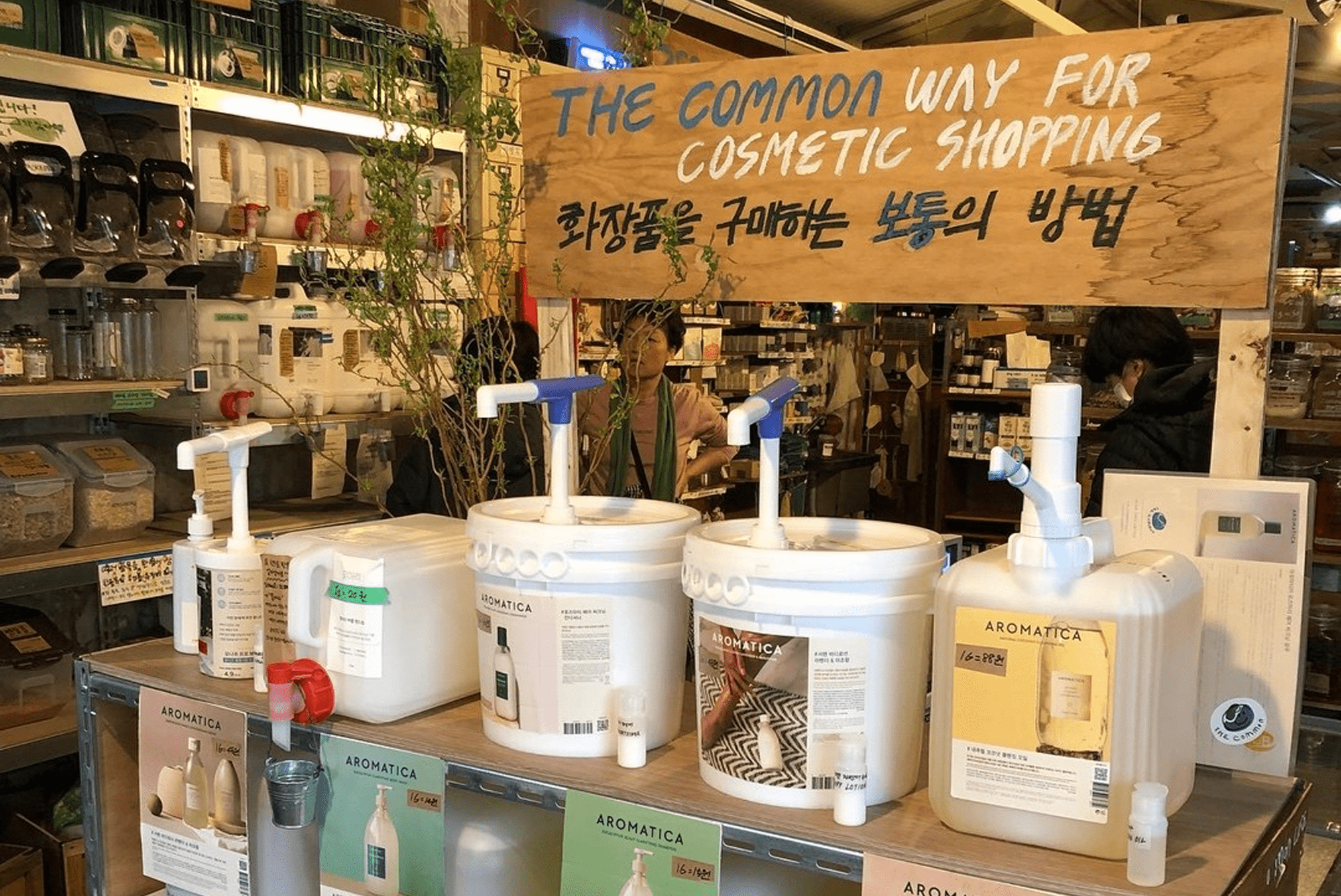

Aromatica does not stop just at developing sustainable packages, but is actively spreading the culture of refilling and reusing containers once they are purchased.

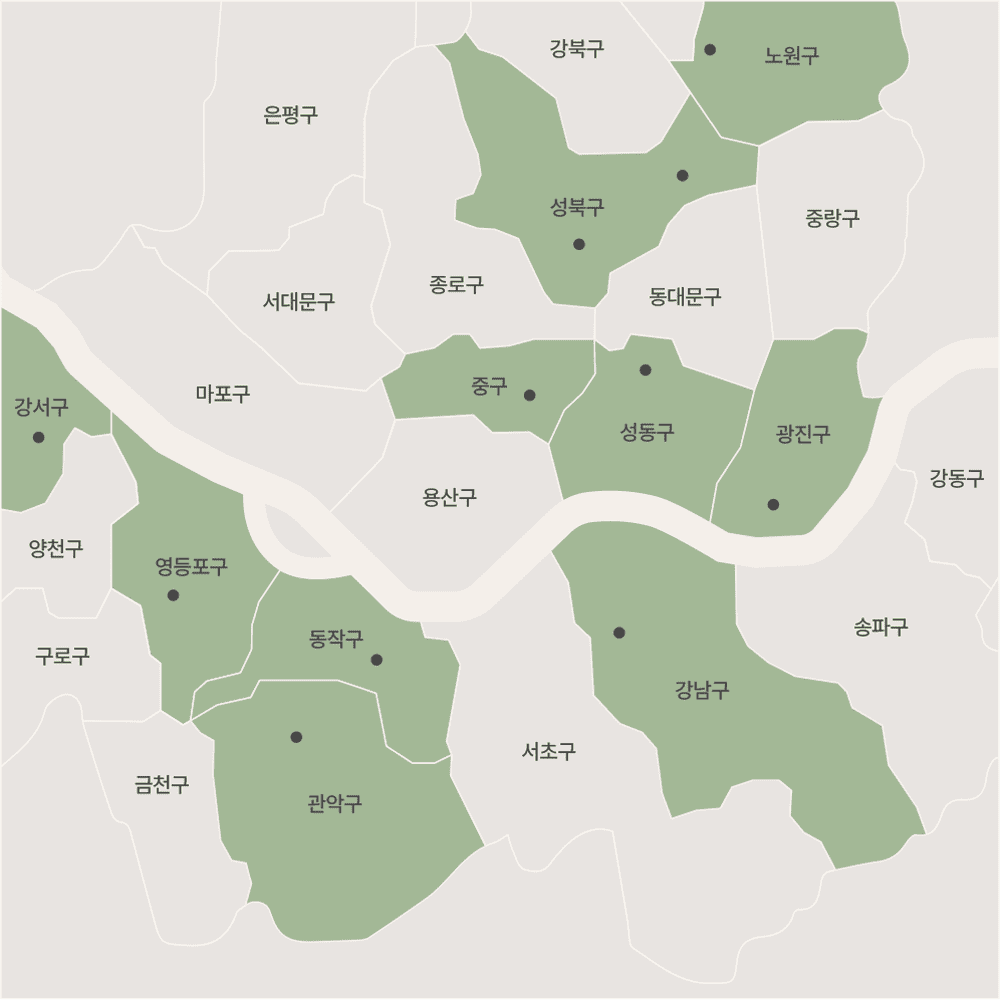

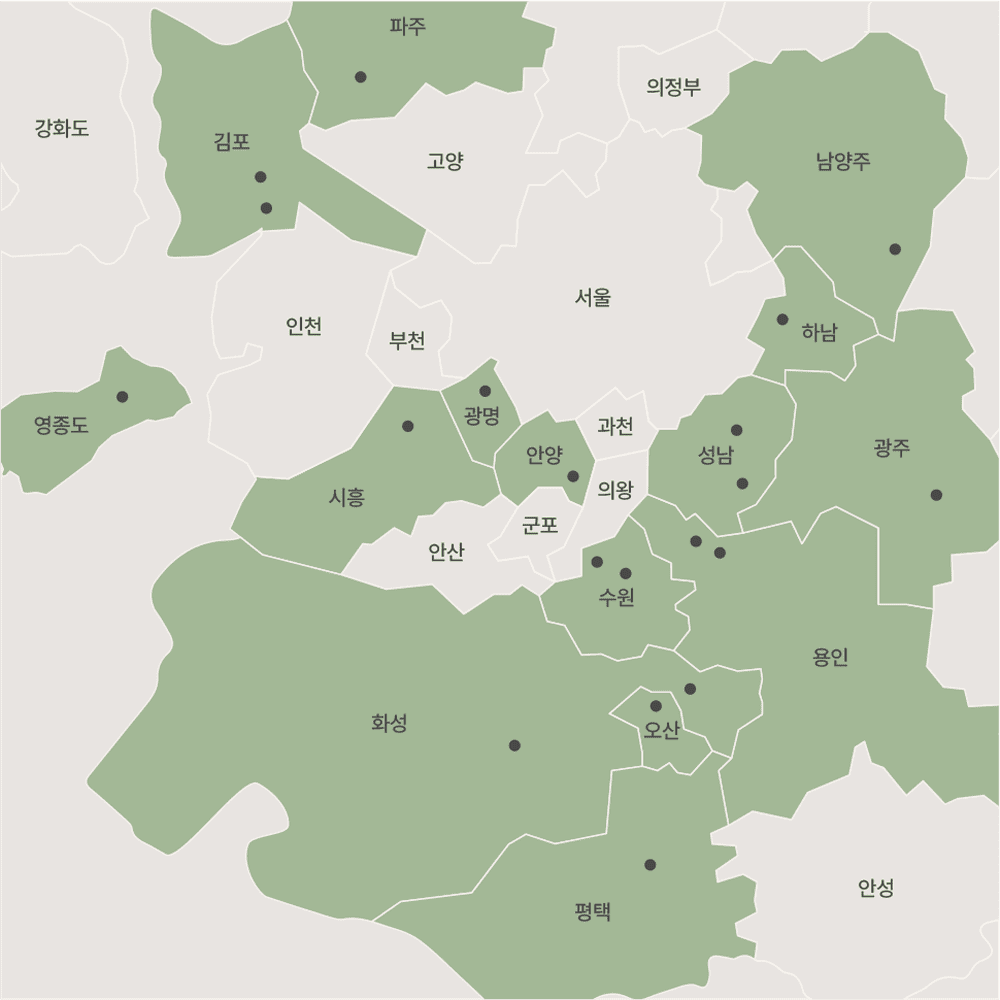

We have partnered with 31 Zero Waste Shops nationwide to spread the culture of refilling for consumers.

@더커먼

@더커먼알맹상점

서울 마포

보틀팩토리

서울 서대문

허그어웨일

서울 강서

1.5도씨

서울 관악

제로띵스

서울 중구

알맹상점 리스테이션

서울 중구

디어에코

서울 광진

에코도모

서울 광진

보탬상점

서울 중랑

비유비웰

서울 동작

덕분애

서울 서초

동그라미리필러리

경기 성남

무해공간

경기 성남

솝리필스테이션

경기 성남

슬기로운생활

경기 성남

에코파레트

경기 광명

용기내 담아가게

경기 남양주

반달서림동백

경기 용인

채움소

경기 중구

지구랑마을이

경기 광주

지생사

경기 용인

미오솜

경기 안양

멜리사센츠

충남 부여

유익한 상점

전남 순천

카페이공

광주 광산

진지한 주식회사

울산 남구

천연제작소(부산점)

부산 북구

심플리파이

부산 수영

그로잉

대구 남구

더커먼

대구 중구

하루한알

경남 창원

카페 아날

경남 거창

천연제작소(양산점)

경남 양산

초록별상점

경북 구미

Aromatica has partnered with 10 hotels/lodging to reduce disposable hygiene product wastes, while introducing refill amenities for which containers can be reused.

@로컬스티치

@로컬스티치 @로컬스티치

@로컬스티치 @제주스테이 비우다

@제주스테이 비우다 @제주스테이 비우다

@제주스테이 비우다* From 2022, free disposable hygiene products cannot be provided for all lodging facilities with 50 or more rooms, and all other lodging facilities from 2024.

로컬스티치 을지로점

서울시 중구

로컬스티치 시청점

서울시 중구

로컬스티치 대전소제점

대전 동구

소소아한옥

충남 공주

국민여가캠핑장

강원 인제

유선관

전남 해남

IJE 호텔

경남 남해

제주스테이 비우다

제주도 서귀포

엉알 이모야

제주도 제주

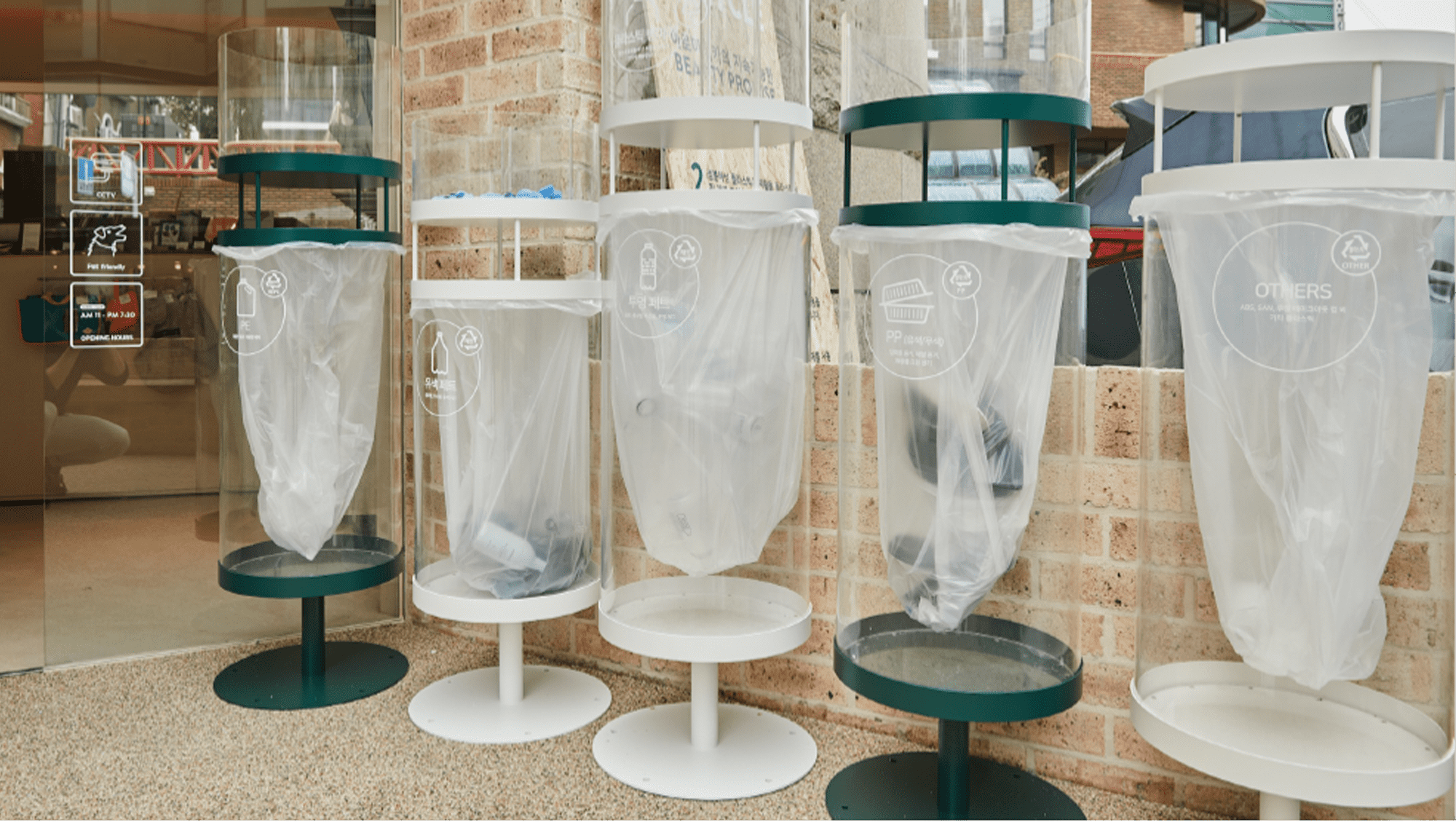

Even if we carefully dispose resources separately by category, most of these become mixed and contaminated at the recycling center. That is why Aromatica has established bases in different regions to collect empty bottles and transparent PET bottles and collect them directly using an electric truck to make Aromatica’s empty bottles. If you wish to JOIN THE CIRCLE of Aromatica, empty out the transparent PET or Aromatica bottles and bring them to your nearest collection base.

AROMATICA collects its product bottles, transparent PET bottles, and plastic bottle caps in a joint effort with zero-waste shops.

AROMATICA's electric trucks pick up PET and bottle caps from collection bases. They are delivered to the recycling flake factory directly without going through screening areas.

20 tons of PET collected by AROMATICA are gathered, washed, crushed, and made into flakes.

Flakes are melted, elongated, and then chopped into pellets. These high-quality pellets turn into recycled plastic containers or merchandise.

This process creates AROMATICA's100% PCR containers. It is how Aromatica envisions our virtuous circle.

That’s because among the numerous plastics such as PET, PP, PS, and PVC, PET can be recycled at the highest quality. PET that completed the process of sorting, crushing, melting, and recycling become the raw materials for making new cosmetic product containers. In order to make recycling materials having high utilization value, we only gather transparent PET not mixed with other materials. We do this because PET with waterproof coating or other additional processes lower its value as recycling materials. The transparent PET that we gather through our partner collection bases go through a process and are reborn into recycled PET.

Also, the minimum batch amount needed to crush these transparent PET gathered from the collection bases and turn them into flakes is 10 tons. If 10 tons are not gathered, it must be mixed with plastics having lower value as recycled materials. Our goal is to gather 10 tons to produce grade A recycled plastics with clean resources that we gathered. That’s because no matter how slow and difficult this may be, true recycling starts from here.

Our Goal

collected PET from 2021

Collection Rate

In order to gather more transparent PET, Aromatica has partnered up with Zero Waste Stores. Starting with the capital area, we selected regional bases to install transparent PET collection boxes at each base. When transparent PETs are gathered here, we pick them up directly using Aromatica's electric trucks. Aromatica is looking to expand its field of solidarity so that people who endure working for the environment can take a step closer to a sustainable life.

137.9 tons of carbon emissions is equivalent to the amount of carbon when using about 5,995,662 plastic take-out cups. Aromatica has taken the initiative to reduce plastics and encourages customers to reduce the use of plastics.

Just in 2021, 2,808,767 containers and refill pack products made by recycling waste plastics and waste glass were used.

2,808,767 products manufactured and sold with recycled containers and refill products instead of producing new plastic containers are equivalent to reducing about 137.9 tons of carbon emissions. Aromatica has reduced about 137.9 tons of carbon emissions by using sustainable packages and packaging materials in one year.

In 2021, we managed the plant facility operation hours to cut power usage by 145,390 kW.

Aromatica is continuously researching and developing to create sustainable products and packages. In result, we produced 23 different recycled PET containers, 14 recycled glass containers, single material PE tube, single material aluminum tube, metal-free pumps, and 14 different Zero Waste merch in 2021.

Aromatica does not stop just at developing sustainable packages, but is actively spreading the culture of refilling and reusing containers once they are purchased. We have partnered with 35 Zero Waste Shops nationwide to spread the culture of refilling for consumers. Furthermore, from 2022, free disposable hygiene products cannot be provided for all lodging facilities with 50 or more rooms, and all other lodging facilities from 2024. Aromatica has partnered with 10 hotels/lodging to reduce disposable hygiene product wastes, while introducing refill amenities for which containers can be reused.

In order to recycle containers that no longer have use, we partnered with 30 Zero Waste Shops in the capital area through the JOIN THE CIRCLE campaign to build transparent PET collection bases.

In 2021, we conserved lighting energy at our plant facility to cut electric power usage by 8,400 kW every month.

Aromatica begins with scrutinizing the raw materials of cosmetic products. We take a look at where the raw materials used in products come from and how they were produced. We examine how much electricity and water is used in the raw material cultivation process, and think about sustainable methods for the processing procedure after extracting active ingredients from the raw materials. We set sustainable beauty standards and thoroughly exclude harmful substances based on strict criteria, and create products prescribed with vegan formulas based on bioethics.

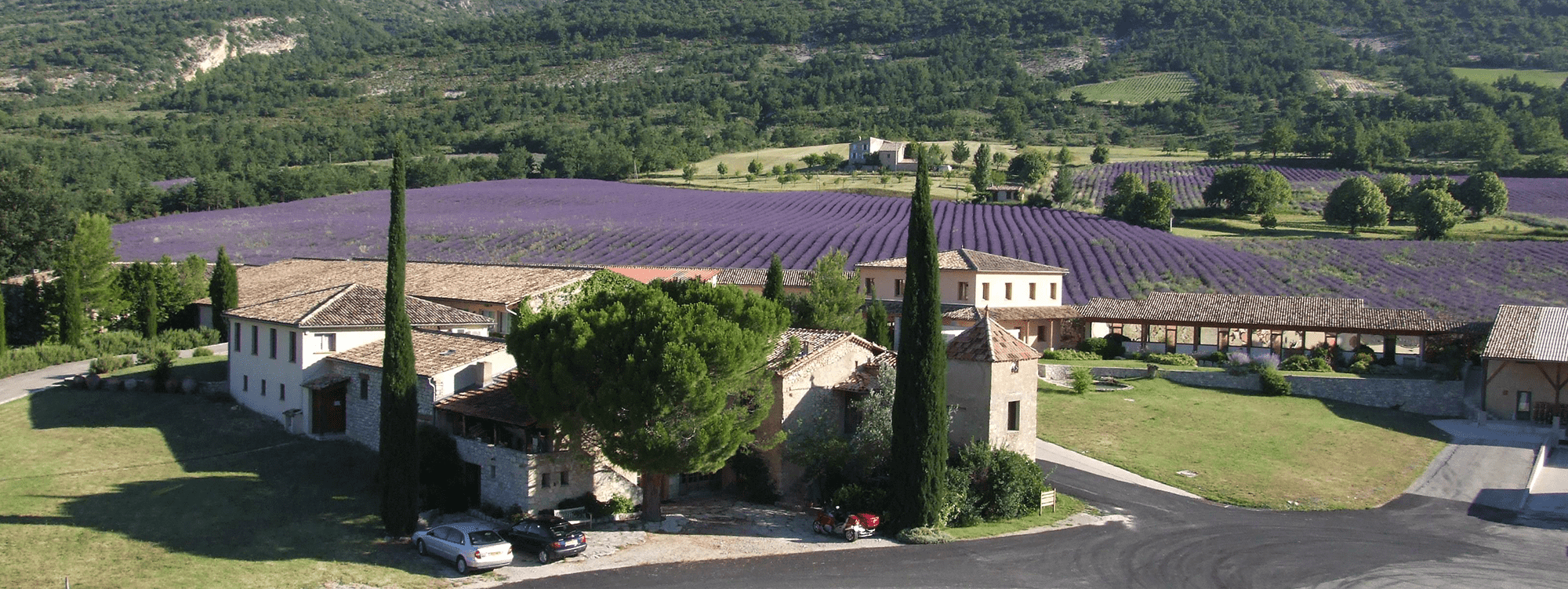

Even when selecting partners, Aromatica consider impact on society and the environment. Aromatica’s essential oil partner practices environmental protection and fair trade to take part in our mission. The essential oil supplier has been continuously participating in donations to establish a culture for preserving lavender and lavandin. In the case of lavender essential oil, it researches ways to use sustainable energy during local distillation. Instead of throwing away the lavender that completed distillation, they are used as compost for growing fruits.

Aromatica has been an active partner of the safe cosmetic product campaign of the US environment organization EWG since 2009, and was the first to introduce EWG to Korea. This has a positive impact on the Korean cosmetic industry, which elevated awareness on material safety. In 2016, Aromatica became the first Korean manufacturing brand to receive the US EWG VERIFIED™ certification, and has completed verification from strict beauty certification institutes since then. Through this process, it built a database on (potentially) harmful substances and took the initiative in setting ‘sustainable beauty standards’ in Korea. Aromatica practices bioethics to prescribe a vegan formula using only plant-derived raw materials. We thoroughly exclude all harmful substances that can have a negative impact on both people and the environment to manufacture products using healthy and safe materials.

We are a registered partner of the Vegan Society, which is the oldest and most prestigious vegan certification institute in the world.

Aromatica acquired EWG VERIFIED™ certifications for 33 products.

The Aromatica production process acquired COSMOS organic cosmetic product manufacturing facility certification in 2019.

In 2011, Aromatica was the first Korean brand to be selected as a EWG safe cosmetic product champion. The EWG safe cosmetic product champion is a title given only to brands that disclose all of its ingredients and pass objective criteria based on various clinical and academic data.

We acquired organic cosmetic product manufacturing facility certification.

The Aromatica production process acquired COSMOS organic cosmetic product manufacturing facility certification in 2019.

Aromatica thinks about ways to save resources in all production processes in which sustainable materials are collected for manufacturing products. Even in the office, we practice even the smallest things to prevent the unnecessary use of energy. Furthermore, we have established an energy-saving smart factory that can reduce energy wastes and recycle energy to reduce carbon emissions.

Aromatica maximizes use of natural lighting in the office and uses lighting with high energy efficiency. Furthermore, in order to enhance the efficiency of lighting facilities, we use light reflectors or light diffusion devices. Instead of lighting up all facilities, lighting is operated only in work areas, and we are always monitoring to make sure that lights are turned off at the end of the day and whether unnecessary lights are turned on.

We inspect and repair the heating/cooling and air conditioning system at least twice a year. We installed a high-efficiency GHP (Gas Heat Pump) air conditioner to reduce electric energy consumption and effectively respond to electric peak loads at specific hours to hugely save on capacity of power substations. We also have fine dust removal devices and central-controlled remote control air purifiers. This is an eco-friendly air conditioning method that responds to air pollution such as yellow dust and fine dust.

Aromatica is doing all it can to conserve energy at the office. We use copiers and fax machines with high energy efficiency and always use standby mode (energy saving button). Paper used in copiers and printers are recycled and we are converting to a paper-free electronic authorization system.

All vehicles owned by the company are electric vehicles. When compared to gasoline vehicles, this can save 13,260 liters of gasoline annually. The headquarters, Zero Station Sinsa, and Osan Plant all have EV charging stations. In addition, flexible work hours are offered to reduce unnecessary energy wastes during heavy traffic hours.

Aromatica completed the energy-saving smart factory in Osan, Gyeonggi-do that can minimize electric consumption and increase energy recycling rates. For cooling and heating, we are reducing carbon emissions through the use of eco-friendly energy that utilizes energy obtained from the outside air temperature.

The Aromatica Osan plant uses sludge generated from the wastewater treatment process to produce and use green soil. Green soil is a type of soil sprayed to revive barren land or wastelands where plants cannot grow. It is fertile enough for plants to grow and is composed of compound organic matter with strong moisturizing and air permeability. Plants grow healthy on green soil.

The plant sets up plans for reducing use of water and regularly inspects and manages water usage. Leaks re checked for regularly and renovation work is underway. Furthermore, meters were installed in areas where water are supplied in large amounts. The overall water pressure applied to the water supply system is managed at appropriate levels.

The Aromatica smart factory has a max power control device. The max power control device manages the max power of electric equipment. This is a smart energy management system that maximizes energy consumption efficiency just by setting the target power usage, and it can save on electricity fees. The smart factory conserves electricity with the max power control device and it is improving consumption efficiency through energy user pattern recognition. In addition, it is improving the operation way through integrated monitoring of cooling and heating equipment, while extending the life of the devices.

The Osan plant is holding lights-off campaigns to conserve use of lights in the plant. Despite some difficulties, this campaign began as part of our efforts to take part in conserving energy, and a person at the plant was designated to turn off unnecessary lights. This is saving 700kw of electricity every month. This reduces 8,400kw of electricity every year.

We are fully equipped with utility facilities to continuously reduce energy usage in the plant. By reducing electricity used for manufacturing one product from 0.212kW to 0.174kW, we have saved on a total of 145,390kW of electricity.

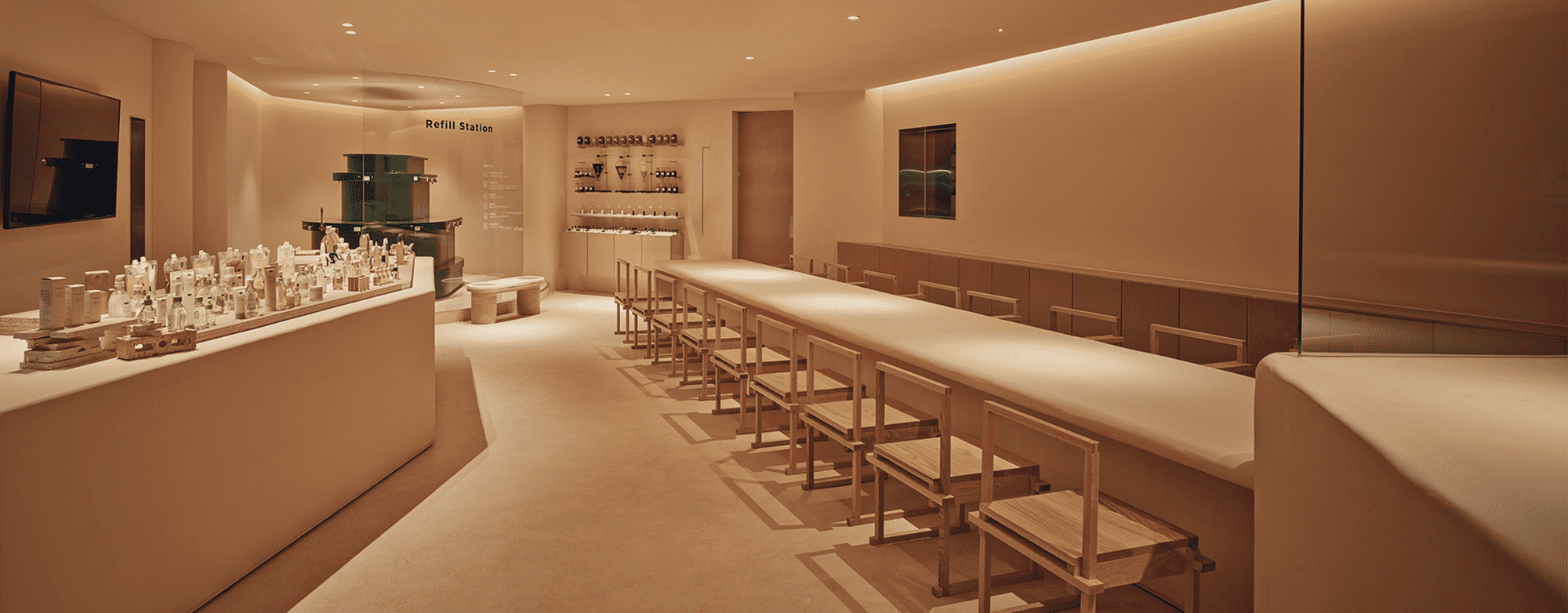

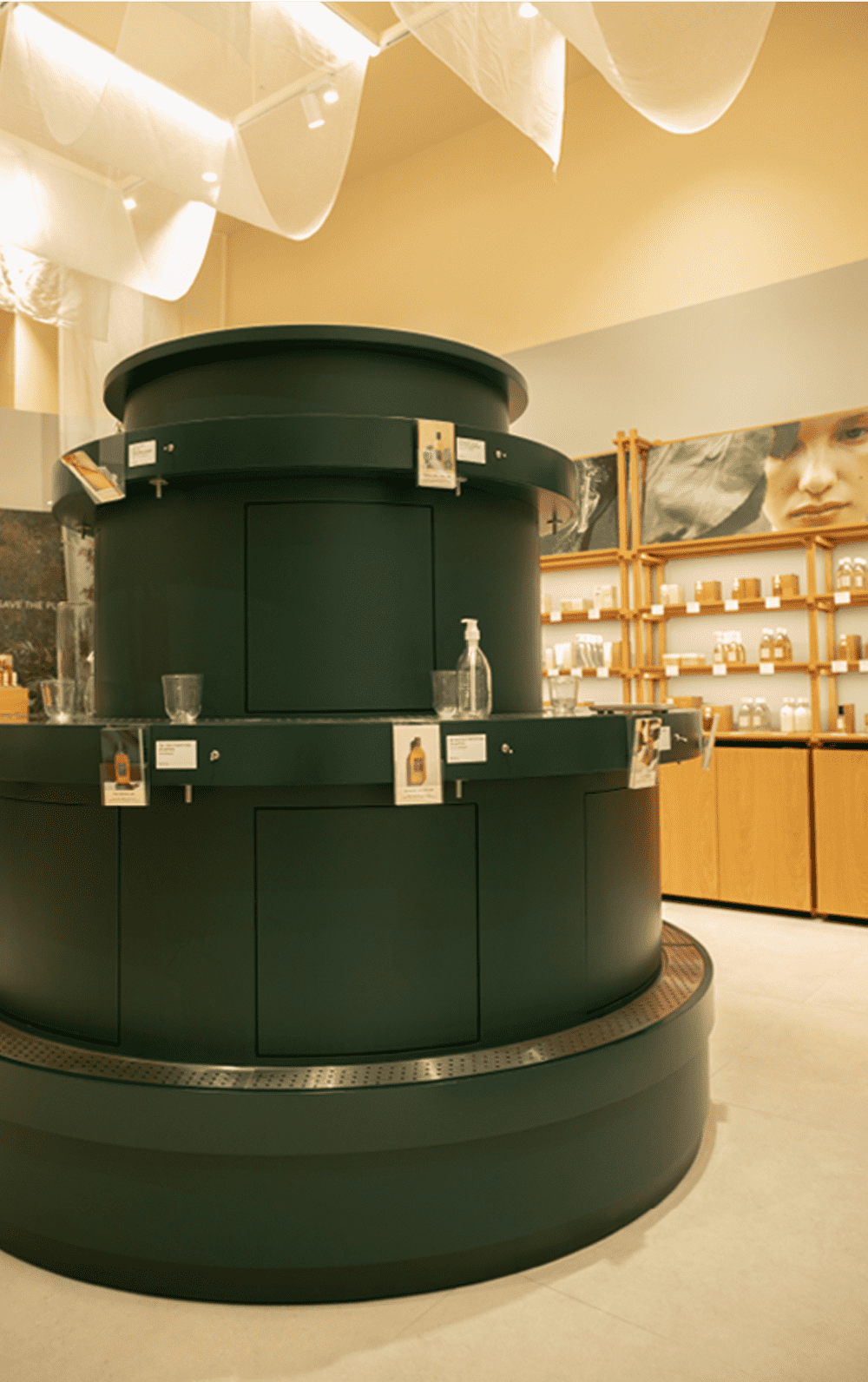

In 2020, Aromatica opened the first plastic recycling and refilling area among Korean beauty brands, and since then, we have been operated refilling areas with Almang Market to take the initiative in practicing zero-wastes. In commemoration of Earth Day on April 22, 2021, we opened a Zero Station in Sinsa-dong to offer a cultural complex where customers can experience the Aromatica brand philosophy that aims for sustainable environment and beauty. Zero Station operates a refill station to spread the culture of reusing containers. In order to establish a culture of recycling, we have been offering opportunities for various experiences so that more people can practice sustainable life such as the Circle Zone that shows the prototypical circulating system of transparent PET and the Aromatherapy Zone for experiencing the many different essential oils used in our products.

In commemoration of Earth Day on April 22, 2021, we opened the Aromatica Zero Station. Zero Station is a cultural complex where customers can experience the Aromatica brand philosophy that aims for sustainable environment and beauty. In order to allow more people to practice sustainable life, we added spaces such as a tea cafe, aromatherapy zone and plastic mill to the existing brand experience hall.

Zero Station renewed the interior and exterior by reusing the furniture and waste materials of ‘House of Aromatica’ located on the second floor of the Aromatica building. Scan the QR codes hidden on furniture and the floor to see videos of Zero Station upcycling project.

The steel table used in the House of Aromatica was repainted and waste glass pieces were used on the top plate to produce this table like a terrazzo that can be combined and reused with steel furnishing.

By repeating the process of melting thousands of face masks were melted with hot air and then cooling and hardening, it was reborn as a chair with the durability of strong and tough plastic.

This is a piece made by using plastic chairs used at the House of Aromatica by covering paper porridge made by wastes, egg cartons, etc. collected by an artist on the plastic chair.

Waste glass from a glass factory was processed and mixed with existing pebble stone floor materials for this terrace floor.

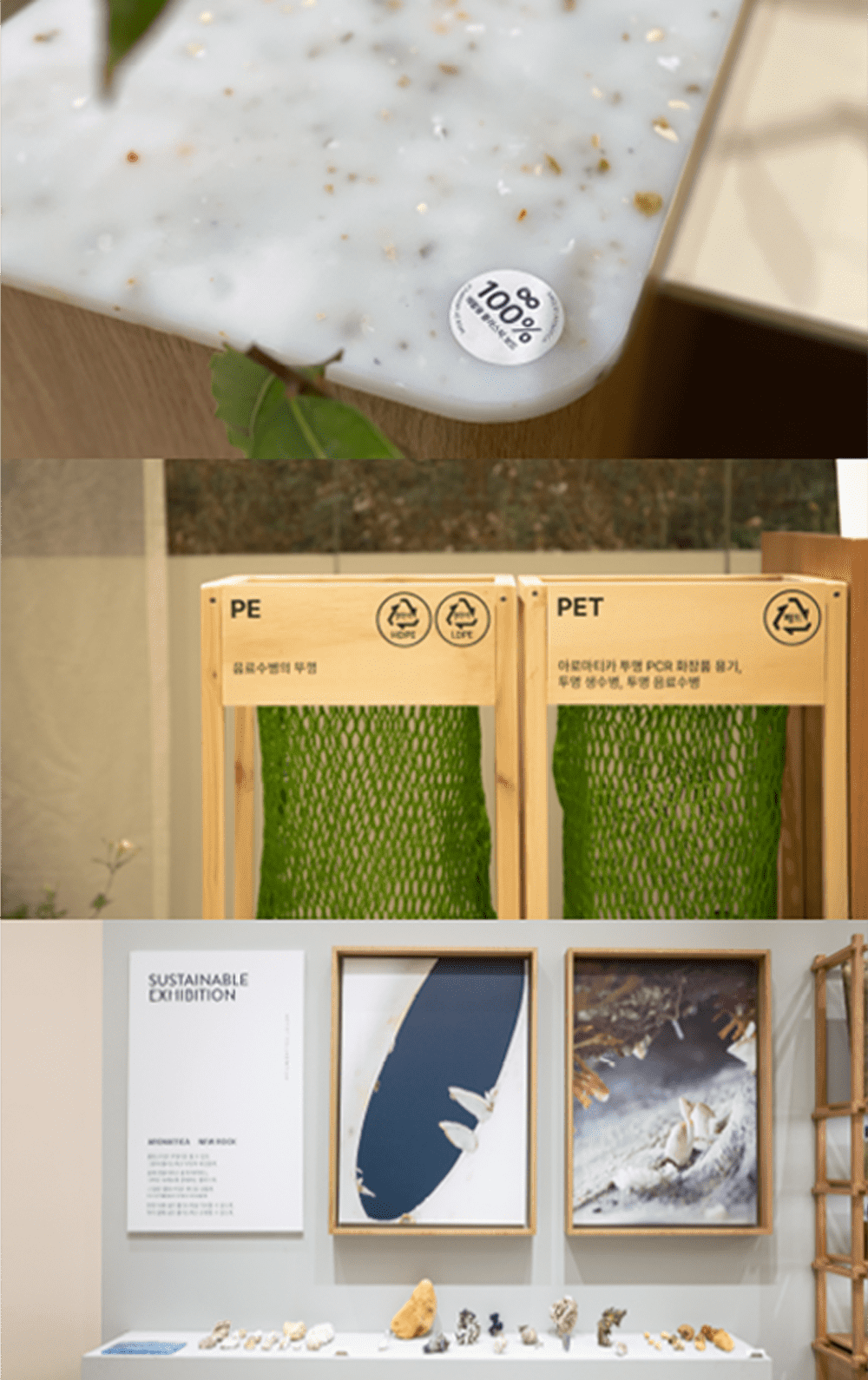

Aromatica Zero Station that was opened in Starfield Hanam includes a transparent PET separate collecting area for practicing prototypical resource circulation through bottle-to-bottle, furnishings using boards made by recycling lids, a refill station where customers can purchase just the contents by bringing in their empty bottles, and New Rock by Hanna Jang that gives the message about plastics that do not decompose in nature.

Aromatica works on allowing employees to coexist with the company. We do our best so that employees can enjoy their work and leisure, and also provides programs that allow employees to feel at ease when going through child birth and raising their children. Furthermore, Aromatica considers the lives of not only its employees, but its neighbors around the world.

In 2019, Aromatica was recognized as a company that advocates family-friendly management, and received family-friend company certification by the Ministry of Gender Equality and Family. In 2020, it was recognized as a company in which employees can find harmony of work and leisure, and received leisure-friendly company certification.

Aromatica donated 29,952 Aromatica products in 2021 for senior citizens, disabled persons, and children who need cosmetic products cannot afford it. It also donated a total of 159,920,000 KRW. It regularly sponsors children both in Korea and abroad with unstable family environments and financial difficulties, and supports medical expenses for children who are ill but don’t give upon their dreams. We are also providing support for senior citizens living alone so that they may improve their quality of life and stay healthy in their old age.

There were 15 employees at Aromatica who gave birth from 2017 to 2021. Eleven of them took maternity leave and 100% returned to work. Aromatica offers customized care for each period from pregnancy to child care. A congratulatory party for pregnancy is held and working moms who just gave birth are given one-year maternity leave. In addition, mothers can choose to shorten their working hours by two hours for 1.5 months before taking maternity leave and for one year after taking maternity leave. We also provide one-month paid maternity leave and postnatal care expenses. These programs help create an environment for working mothers to work without having to worry about giving birth and raising their children.

한 해 동안, 폐플라스틱/폐유리를 재활용해 만든 용기와 리필팩 제품의 판매수

한 해 동안, 폐플라스틱/폐유리를 재활용해 만든 용기와 리필팩 제품의 판매수

한 해 동안, 폐플라스틱/폐유리를 재활용해 만든 용기와 리필팩 제품의 판매수

한 해 동안, 폐플라스틱/폐유리를 재활용해 만든 용기와 리필팩 제품의 판매수

한 해 동안, 폐플라스틱/폐유리를 재활용해 만든 용기와 리필팩 제품의 판매수